Return On Investment of Biofilm Monitoring [Download this white paper as PDF file]

Nowadays, the industry is investing many resources in the optimization of production and processes, implementing also the so-called "Industry 4.0" initiative. For what concerns cleaning and sanitation treatments, the technological advances of the last few years allow for much more efficiency, compared to the past. Despite this fact, the current approach to cleaning and sanitation is mostly the same that was applied 20 or 30 years ago. Most industries use water or other liquids, in their production and in other processes (cooling, rinsing, etc.). To prevent the large number of issues caused by bacteria proliferation, they spend a large amount of money in physical and chemical treatments - but, in most cases, they do not even check if these are applied wisely.

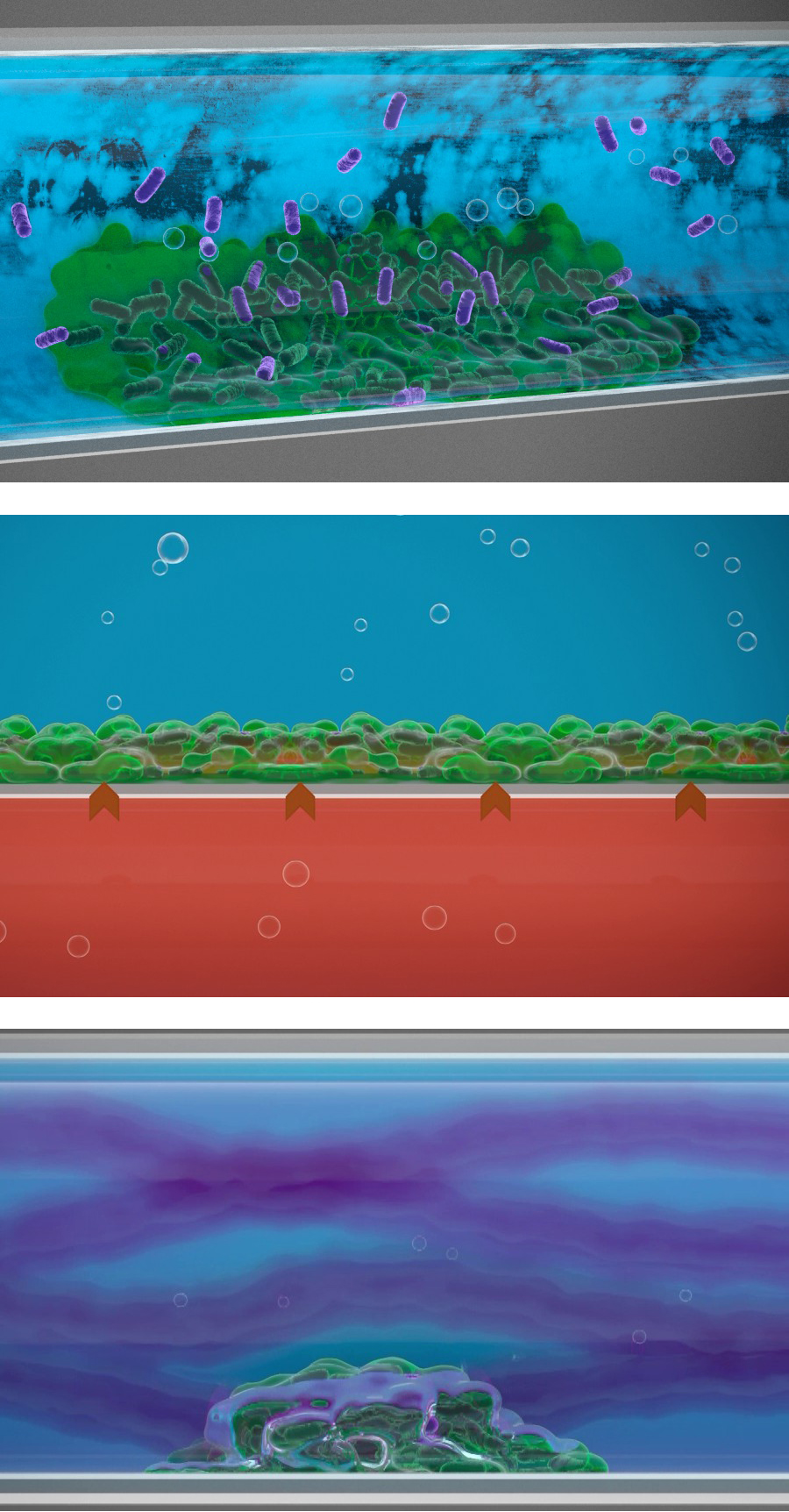

Indeed, the microbial detection techniques usually applied in these cases are still largely focused on free-floating bacteria. Unfortunately, it is well known that 90% of total bacteria live attached to surfaces (in a layer usually known as "biofilm"), and not free in the liquid. Such biological layer represents the most important source of microbial contamination, and the root cause of most bacteria-related problems. Indeed, biofilm is responsible for a number of issues, including equipment failure, reduced efficiency, microbially induced corrosion (MIC), energy loss, resistance to antimicrobial treatments and many more. Indeed, biofilm is much more difficult to remove, compared to free-floating bacteria, due to self-produced exopolymeric substances (EPS) that shelter it from the action of biocides. For all of these reasons, sampling and analysis of the liquid, which represents the standard approach to microbial control, do not provide a real indication of treatment efficacy. Indeed, such method only allows to monitor free-floating bacteria, providing no indication about biofilm growth and elimination.

On the contrary, biofilm growth is the key process indicator that should be monitored to ensure the safety of a system, and to prevent the issues mentioned above. This is because, in order to guarantee the highest efficiency of sanitation, the treatment should be applied when biofilm is young, and thus easier to remove. Even if this concept is widely accepted, both by scientists and by professionals working in the field, unfortunately most industrial protocols for microbial control do not include biofilm monitoring.

With this respect, ALVIM Srl strongly promotes a radical shift in the approach to cleaning and sanitation treatments. ALVIM Sensors are based on electrochemical principles, which allow to monitor biofilm growth in a highly sensitive and specific way. This Technology provides an 'early-warning' signal, indicating the very first phase of biofilm growth - and thus the best time to apply sanitation treatments. In addition, ALVIM Technology detects microbial growth online and in real time - without the need to wait for hours or days, as it is the case of common techniques for liquid sampling and analysis. Several hundreds of Customers worldwide, including the biggest players of Food&Beverage, Oil&Gas, Pulp&Paper, Cooling systems, HVAC and others are employing ALVIM Technology since several years. Thanks to ALVIM Sensors, Customers can optimize their sanitation treatments, based on real needs - as a result, they can ensure the safety of their products and working environment, safeguard their equipment, and prevent issues.

Thanks to the advantages offered by ALVIM Technologies, the Return On Investment (ROI) can be very fast.

In a large industrial plant, applying biocides or other sanitation treatments, the ROI can be up to 100% in just one month. Indeed, in this kind of industry it is quite common to spend one million USD per year and more in biocides - and ALVIM Biofilm Monitoring Technology can allow a reduction in the use of these chemicals of up to 90%.

In a Food&Beverage production plant with a bacterial contamination, the ROI can be of 100% in just one week. Indeed, while in this industrial sector saving on chemicals is less relevant, ensuring the microbial safety of the final product - and thus of end-users - is the most important goal. By means of ALVIM Technology it is possible to ensure the optimal sanitation of the system, to safeguard production and to prevent customer's complaints - avoiding dramatic scenarios including batch recall or, even worse, outbreaks.

In a power plant affected by biofilm growth, the ROI can be of 100% per day. Indeed, it is well known that biofilm is even more insulating than mineral deposit - for this reason, microbial slime plays a detrimental effect on heat-exchange efficiency. Making possible to keep biofilm growth under control, ALVIM Sensors allow to extend the lifetime of equipment, and to boost power production up to 30%.

|

Do you have biofilm-related issues?

|