Mineral water bottling [Download this application case as PDF file]

In water bottling plants, bacterial growth on surfaces (biofilm) can represent a serious threat to human health, since this microbiological layer is the ideal environment for the survival and growth of pathogenic bacteria. Moreover, biofilm can be up to 1000 times more resistant to sanitation treatments with respect to free-floating bacteria. Detection of biofilm and prevention of possible biological contaminations is, therefore, of primary importance.

In this water bottling plant, the sanitation treatment of pipelines and tanks was applied at predefined times. No verification procedure was carried out to check the effectiveness of this treatment, before the installation of ALVIM System.

Taking into account that ALVIM probe indicates:

- the dosage of oxidizing agents through a sharp and large increase in the Signal, and

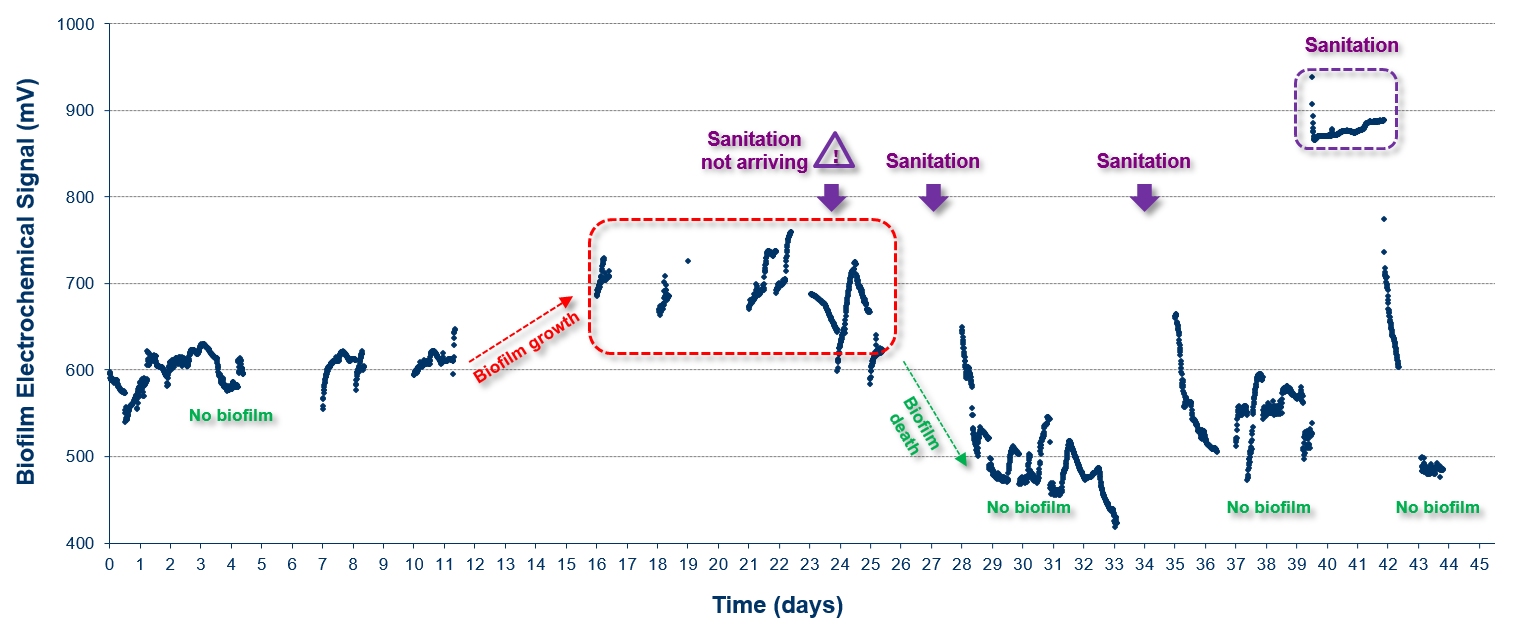

- biofilm growth through a relatively slow increase in the Signal of 150 mV and more, with respect to the baseline value (in this case about 550-600 mV, marked in the figure as "No biofilm"),

after some weeks of use of the ALVIM Biofilm Sensor, the plant technical staff was able to detect that, in the pipe where the probe was installed, the cleaning treatment was not working appropriately. Starting from day 16 (see the graph), ALVIM signal indicated biofilm growth. Moreover, when sanitation was applied (see day 23) the sensor did not detect any oxidizing agent. The technical staff discovered that, due to a wrong configuration of a valve, the line where the Sensor was installed was never treated (see figure below).

Sanitation procedure was thus modified, to solve the problem. Following this change (see the graph, from day 26), ALVIM signal decreased below risk level and it never highlighted biofilm growth again. At the same time it can be observed how, following the solution of this problem, the application of sanitizer was detected by the sensor (see days 39-41).

Thanks to the ALVIM technology, it was possible to keep track, in real time, of both the application and the effectiveness of the treatments aimed at preventing bacterial growth inside the plant.

|

Do you have a similar problem with biofilm?

|