Frequently Asked Questions (FAQs) [ Download all FAQs as a PDF file ]

- What is biofilm?

- Why water sampling and laboratory analyses are not enough?

- I noticed large fluctuations in the amount of bacteria in my industrial water. What can be the reason?

- Which are the differences between a fouling sensor and a biofilm sensor?

- What are the advantages of the ALVIM Technology compared to the sensors available on the market?

- How does the System work? What does it monitor?

- Is an ALVIM Sensor the same of an ORP probe?

- Which is the sensitivity of the ALVIM probe? Do I need such a high sensitivity? In my application field we can afford XX microns of biofilm

- What are the working conditions of ALVIM sensors?

- Which communication protocols does the ALVIM System support?

- How many probes do I need to monitor a plant / water line?

- How long does it take to learn to use the ALVIM Biofilm Monitoring System? Does ALVIM Srl provide training/support?

- In which industries is the ALVIM System used?

|

If you did not find the answer to your question

|

What is biofilm?

The term biofilm refers to the layer of microorganisms (bacteria, diatoms, fungi, etc.) that grows on any surface in contact with water or other liquids. Most often (including this website), this term is used to indicate bacterial biofilm. It has been demonstrated that biofilm can grow even in extreme conditions, causing damages that can range from Legionella contamination to Microbiologically Influenced Corrosion (MIC).

Why water sampling and laboratory analyses are not enough?

It is universally accepted that, once the first bacteria coming from the liquid bulk settled on a surface, biofilm growth continues almost independently from the bacteria free-floating in the liquid.

For this reason it is useless to analyze water samples, for what concerns biofilm monitoring. Moreover, laboratory culturing techniques, used by default for microbiological analysis of water samples, are able to detect less than 1% of the bacteria really present. Indeed, it is well known that more than 99% of the bacterial species present in a sample will not grow in laboratory culture media.

I noticed large fluctuations in the amount of bacteria in my industrial water. What can be the reason?

Here you can find a White Paper discussing this topic in details.

Which are the differences between a fouling sensor and a biofilm sensor?

The term fouling indicates any kind of deposit accumulating on a surface, including minerals, proteins, fats, microorganisms, etc. Therefore, a fouling sensor detects generic deposit, with no specificity.

On the contrary, the term biofilm refers only to the layer formed by microorganisms, in particular bacteria. So a biofilm sensor detects only microbioogical growth.

For such reason, the information provided by a biofilm sensor is more specific than that given by a fouling sensor.

For example, if you want to trigger a sanitation or biocide treatment, or to check its effectiveness, you shall use a biofilm sensor, not a fouling sensor. Indeed, the biofilm sensor can tell you if microorganisms are growing or not, and if a sanitation treatment is really effective.

What are the advantages of the ALVIM Technology compared to the sensors available on the market?

Compared to many biofilm sensing techniques applied in commercial devices (e.g. measurement of heat exchange, light scattering, turbidity, electrochemical impedance, vibration response of the monitored surface, diffusion limitation) the ALVIM Technology offers important advantages:

∙ actually detects biofilm, not other kinds of deposit/fouling (e.g. calcium carbonate, etc.); this is extremely important, since these two different kinds of fouling requires different treatments;

∙ has a very high sensitivity, i.e. detects biofilm initial colonization phase; indeed, many biofilm related problems, such as Microbiologically Influenced Corrosion (MIC), start as soon as the first bacterial spots appear on a surface.

Compared to the mentioned approaches, electrochemical techniques give the advantage of an early-warning monitoring of biofilm growth. Some of the electrochemical sensors available on the market produce an environment that encourages biological growth on their sensitive surface, therefore bacterial growth may occur before on those instruments with respect to plant components / pipelines. This means that the data provided by those sensors could be an esteem/forecast of plant future conditions, however it is not possible to confirm this, and from the scientific point of view this is highly unlikely. In any case, such information is not a view of the actual presence of biofilm in the water system to be monitored. The ALVIM sensor, instead, measures the natural electrochemical activity of bacterial biofilm, indicating its real presence and extent in a given moment.

How does the System work? What does it monitor?

The ALVIM System monitors the bioelectrochemical signal produced by bacteria. This signal is directly linked to the biological activity of bacteria, and it is proportional to the surface area covered by biofilm. Therefore the ALVIM System monitors just (living) bacteria, not other kinds of fouling (e.g. mineral deposit, fats, proteins, etc.).

More info about ALVIM working principle are available on the research paper:

Exploiting a new electrochemical sensor for biofilm monitoring and water treatment optimization - Published on Water Research 45 (2011), pp. 1651-1658

Is an ALVIM Sensor the same of an ORP probe?

Definitely not. Some Customers ask this question because both the results of ALVIM Sensors and of ORP probes measurement are expressed in mV. But ALVIM measures biofilm electrochemical activity, while ORP measures oxidation-reduction potential. The difference can be easily understood giving a look at this application case.

Which is the sensitivity of the ALVIM probe? Do I need such a high sensitivity? In my application field we can afford XX microns of biofilm

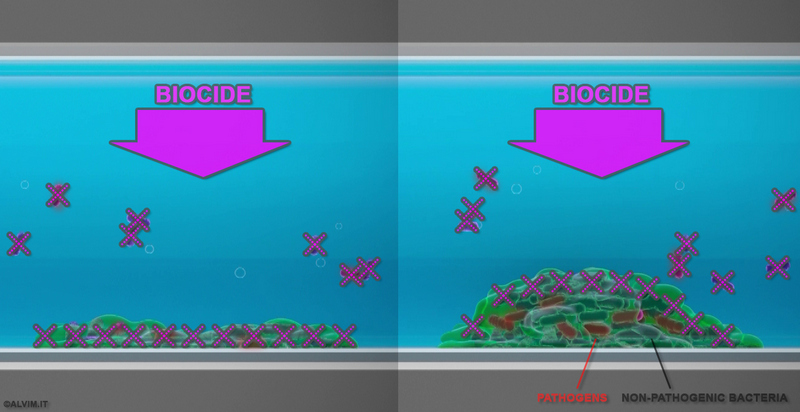

The ALVIM sensor monitors the first layer of biofilm (1-100% of surface covered by bacteria). For what concerns cleaning treatments and sanitation, this is the most important phase of biofilm development, since biocide treatments applied during the first phases of biofilm development provide the best results. If cleaning/sanitation treatments are applied when biofilm is mature, their efficacy is greatly reduced, since the Extracellular Polymeric Substances (EPS) produced by bacteria shelter them from external agents.

What are the working conditions of ALVIM sensors?

Please refer to the technical datasheets.

Which communication protocols does the ALVIM System support?

Please refer to the technical datasheets.

How many probes do I need to monitor a plant / water line?

The suggested number of probes to be installed strongly depends on the structure of a plant / water line: if there are similar conditions in the whole water system, one or few ALVIM sensors can provide enough information about biofilm development inside the whole plant. If just one sensor is going to be installed, a "worst case approach" is suggested, installing ALVIM sensor where biofilm growth is expected to take place sooner. With the purchase of the ALVIM System, our Technical Staff provides a free-of-charge support to evaluate the best installation point(s) inside your plant (if needed).

How long does it take to learn to use the ALVIM Biofilm Monitoring System? Does ALVIM Srl provide training/support?

All the users of the ALVIM System have been able to manage it completely independently after a few weeks of use. During such period, ALVIM Srl provides free-of-charge support for the use of the System and the interpretation of collected data, that does not require any particular expertise.

In which industries is the ALVIM System used?

The ALVIM Biofilm Monitoring Technology is used in the Food&Beverage, Pulp&Paper, Oil&Gas, Power Production, and many other fields. This System showed to be extremely useful also for Legionella prevention in cooling towers and hospitals. Some examples are mentioned here. Application cases regarding detection of biofilm in different industrial systems are also available.

|

If you did not find the answer to your question

|