Biofilm & Energy efficiency [Download this white paper as PDF file]

The improvement of energy efficiency within the industrial sector is, currently, a hot topic at global level. Indeed, this is one of the targets of the 'Industry 4.0'' approach, consisting in the integration of new technologies for the optimization of industrial production. Despite the importance of energy optimization is well understood, global progress witnessed a slow-down in recent years, according to the Energy Efficiency Report 2019, from the International Energy Agency (IEA). Much more could be done to answer such an important need for our society. With this aim, new technologies should be implemented to boost energy efficiency in the industry, in particular regarding water treatment. Indeed, water is an essential resource, largely employed in industrial sites of any kind. As a consequence, water treatment is a considerable source of energy consumption. With this respect, the huge influence of microbiology is often overlooked. In particular, bacterial growth on surfaces (usually known as "biofilm") causes a number of problems, ranging from energy loss to corrosion, equipment failure, reduced performances, and resistance to antimicrobial treatments. More than 90% of bacteria live in biofilm, not free in the liquid. Moreover, this layer of bacteria is much more difficult to remove (up to 1000x) than free-floating microorganisms. Some examples showing the effect of biofilm on energy efficiency are discussed below.

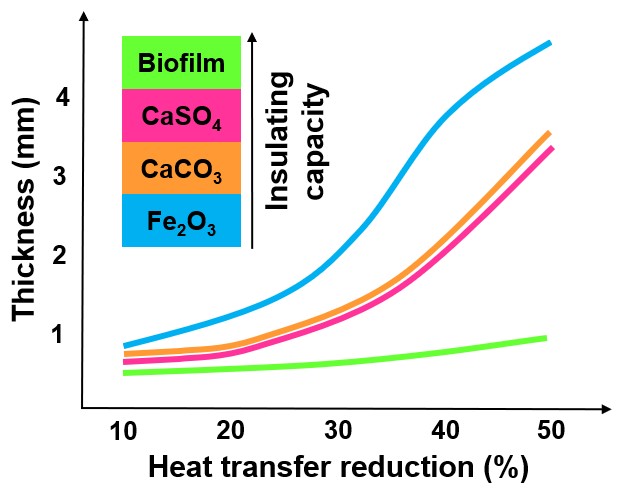

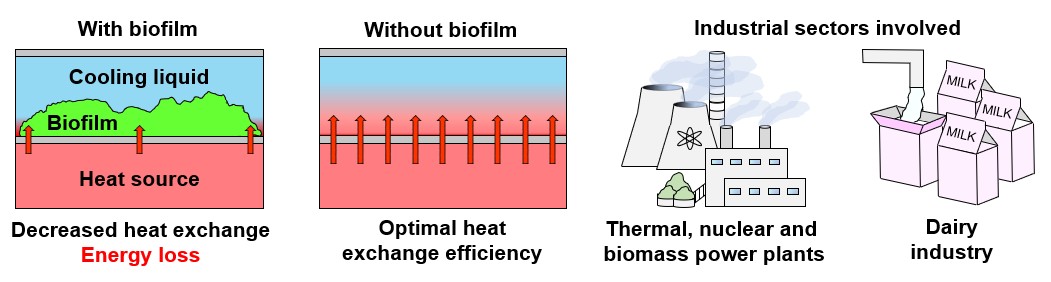

In a heat exchanger, a major component of any power plant, a 20 microns thick biofilm can cause up to 30% decrease in thermal efficiency. Indeed, biofilm is considerably more insulating than mineral deposit. When comparing these two kinds of fouling, less than one millimeter of this microbial layer reduces heat transfer more than several millimeters of inorganic deposit. For this reason, biofilm growth on heat exchangers accounts for a large decrease in efficiency and a huge energy loss. To avoid such problems, biofilm growth should be limited as much as possible. This result can be achieved only if cleaning treatments are applied during the initial stage of bacterial growth. Otherwise, the microbial colonization of pipelines, with its effect on heat exchange, will not be eliminated. This problem impacts all the industries where heat exchangers are used. These include thermal, nuclear and biomass power plants, along with Dairies and, more in general, Food&Beverage production plants, where pasteurization, for example, is a common practice.

A real case-study, about the effect of biofilm on energy production in a thermal power plant, and the resolution of related problems through biofilm monitoring, is discussed in the application case available here.

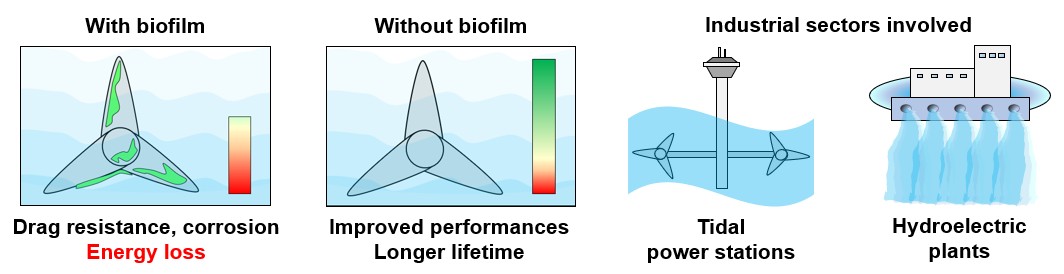

When it comes to renewable energy production, the contribution of green technologies to the global energy balance is progressively increasing. Within this context, tidal power, hydroelectric and OTEC (Ocean Thermal Energy Conversion) are playing a very important role. These plants exploit the natural power of water to produce green energy, contributing to the reduction of carbon dioxide emissions. Most of the surface, engineering components and equipment of these plants are located underwater, thus they are targeted by biological fouling. All surfaces in contact with natural water are colonized by biofilm, which leads to the phenomenon of microbially influenced corrosion (MIC). This results in a lower energy production, due to equipment deterioration and decreased performances. In addition, biofilm also leads to increased drag resistance, which is another source of energy loss. Last but not least, biofilm paves the way to the growth of macrofouling (mussels, barnacles, etc.), which causes even more problems.

To prevent this kind of issues, biofilm monitoring on underwater surfaces is extremely important. Such a proactive approach leads to improved energetic performances and longer equipment lifetime, when applied in combination with specific coatings, appropriate antifouling strategies, and proper cleaning treatments.

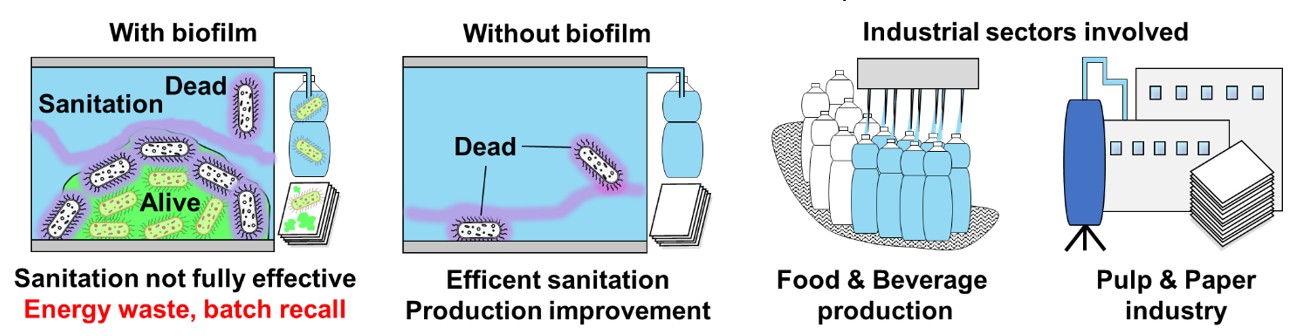

Biofilm is an ubiquitous problem in all industrial environments, in particular in those where water is largely used. In Pulp&Paper production, for example, biofilm is responsible for extensive damage to both machinery and final product. The same is true for Food&Beverage industries, where the direct threat to consumers' health makes the problem even more serious.

For these reasons, thorough sanitation treatments of water pipes are commonly performed, to remove microorganisms and, in particular, pathogens. The presence of biofilm, acting as a shelter to bacteria, makes sanitation treatments less effective. As a consequence, higher dosage of biocides and repeated cycles are needed, with a large waste of energy. Indeed, operational efforts (supervision, refill of chemicals, etc.) and instrumentation (dosing systems, pumps, heaters, monitoring devices, etc.) are required to perform such treatments. Furthermore, working in suboptimal sanitation regime often leads to the contamination of the final product. In this case, any resulting batch discard or recall implies a waste not only of energy, but also of time, money and raw materials. In order to avoid such a situation, it is important to monitor biofilm growth and to ensure the best conditions for sanitation.

To prevent biofilm related issues and, thus, to increase energy efficiency, it is important to monitor biofilm growth. ALVIM Biofilm Monitoring Technologies offer efficient solutions to this problem. ALVIM Sensors provide a reliable measurement of biofilm growth, on line and in real time. This approach allows to check the effectiveness of biocides, and to optimize the treatment based on the real needs.

|

Do you have a similar problem with biofilm?

|